the broad concept is there, but to progress to wireframing the missing recruitment and participation piece needs to be resolved. what is the participation experience?

there are some basics. the research community puts informed consent up-front, where people are asked to digest a comprehensive description of the project and consent to every possible aspect of their future participation. the benefit is ethical clarity for the researchers, but it’s a big ask of people, leading to research staff intervention and financial incentives to get them over it.

that approach is anathema to commercial digital products, as the manual handling imposes a burden of cost and limit of scale. with the right design, the product sells itself, at scale, for free. key is to have an onboarding process that helps people experience the product’s core value. citizen stories needs that, for the same reason the concept introduces automation to the tagging process – it releases the ethnographic process from onerous labour, unlocking commercial possibilities.

but the ask of the concept entry wasn’t just to apply UX 101, it concluded “this kind of crowd-sourcing is inherently extractive, and we need to turn that around”.

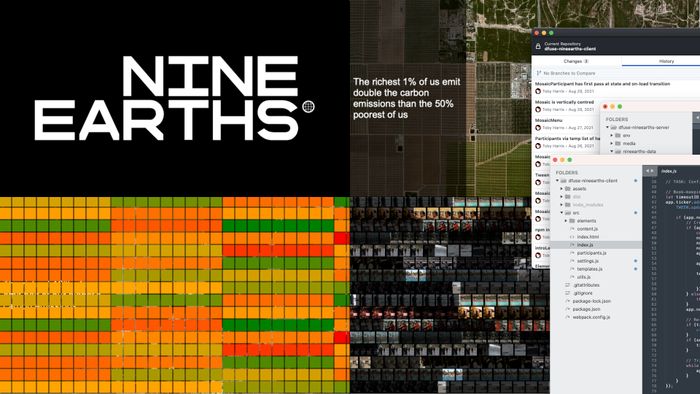

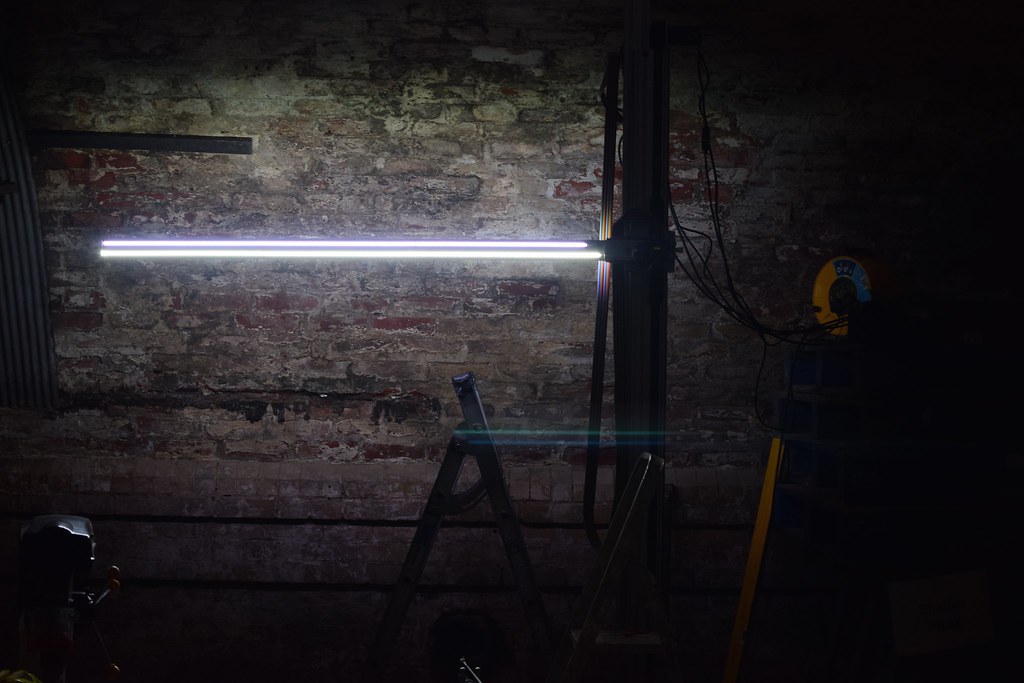

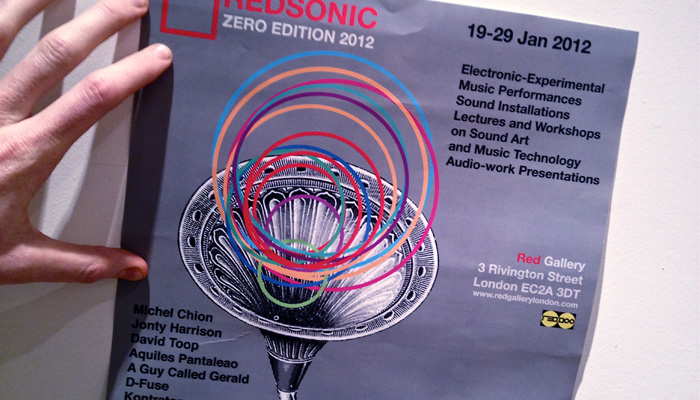

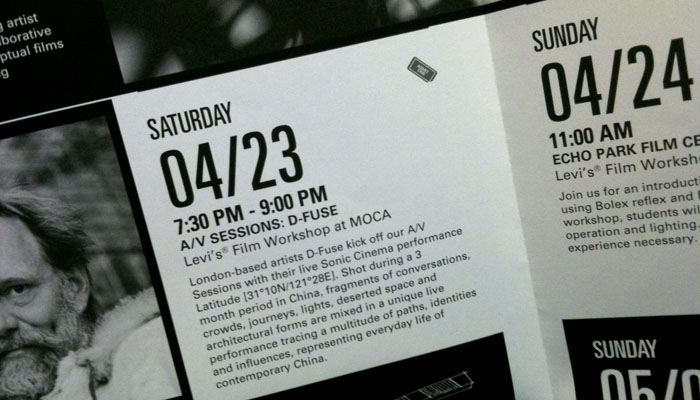

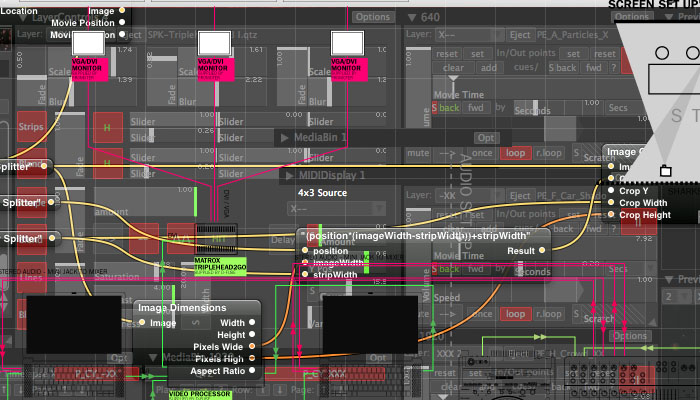

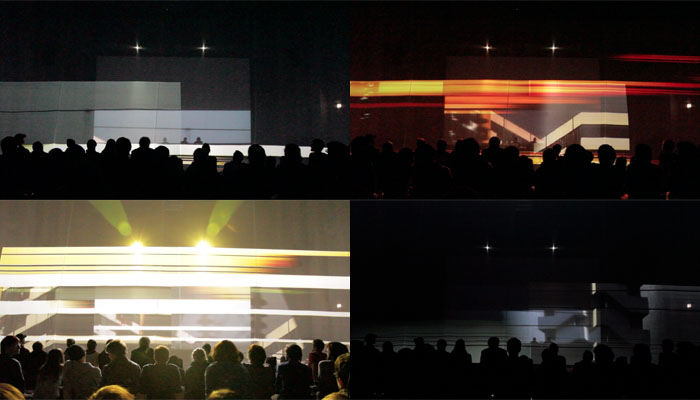

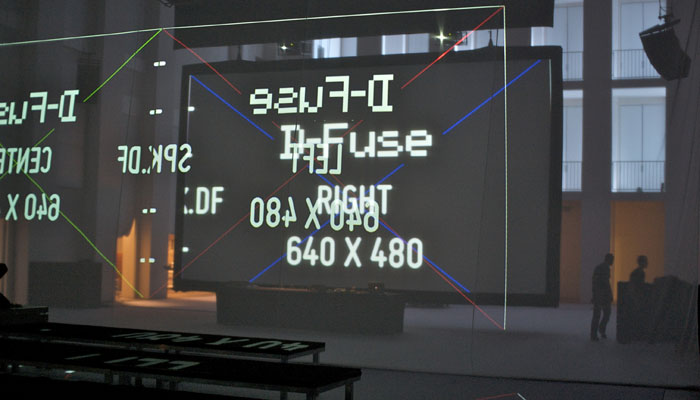

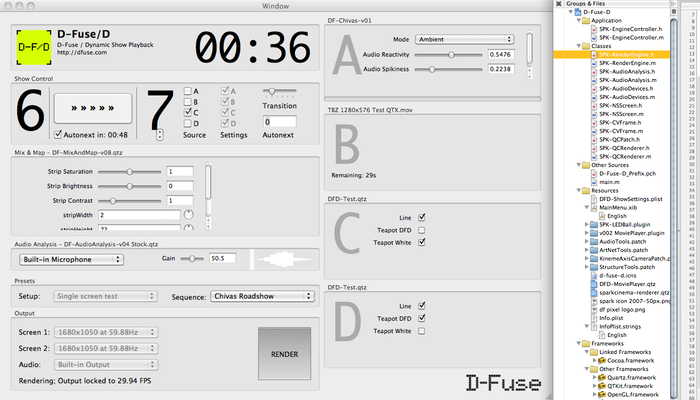

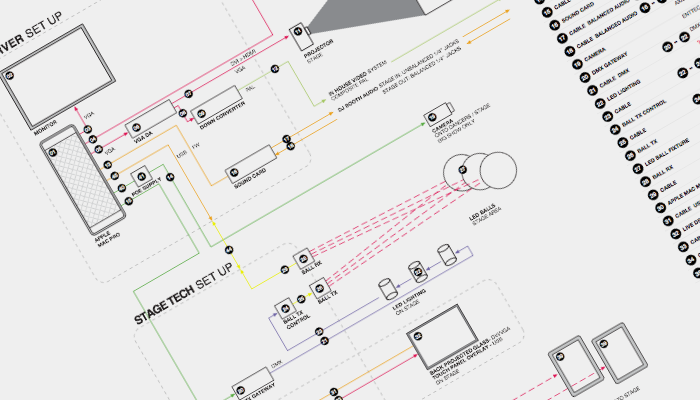

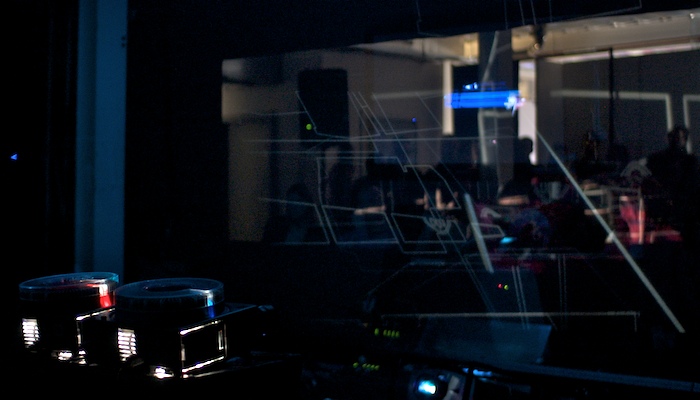

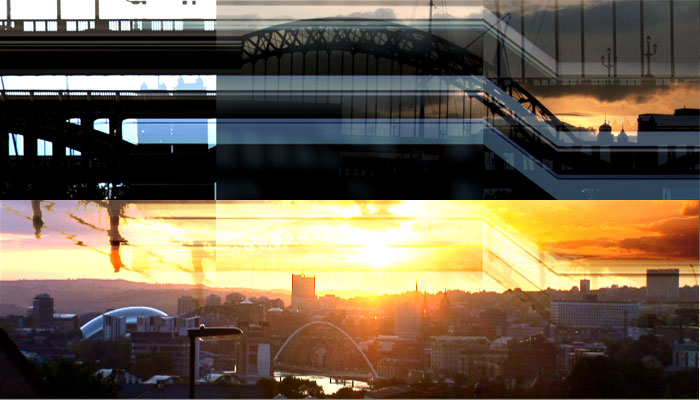

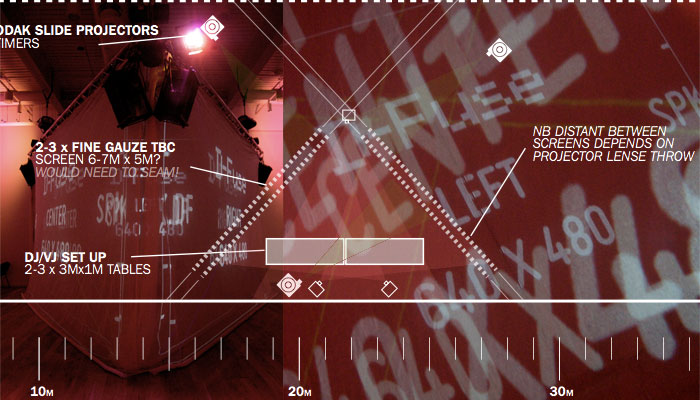

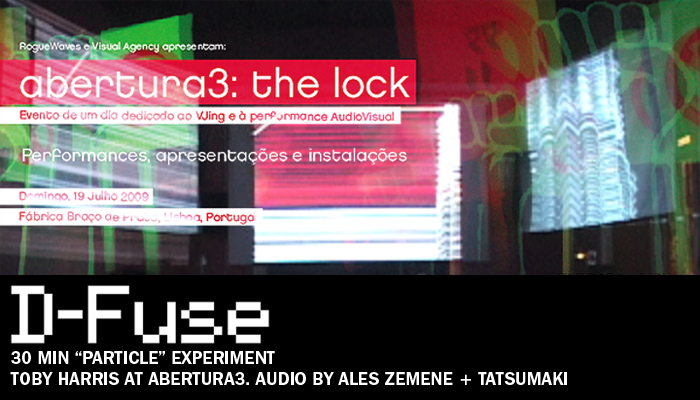

nine earths neatly grounds some thinking on that. the existing piece is a high-end audio-visual installation, and used the research model to get there; it was in part university ethics approved research via kevin walker. d-fuse worked with local partner organisations, and people from these organisations recruited from their community. those organisations then guided their community through the process and ran events that fed back what we were doing with their contributions. it was an ongoing dialogue, people more collaborators than contributors. d-fuse got what it wanted, but value was made and stayed in the community too.

at least that was the idea. the feed back process was frustrated by practicalities; tooling could have helped a lot. better, it all be an integrated digital platform…

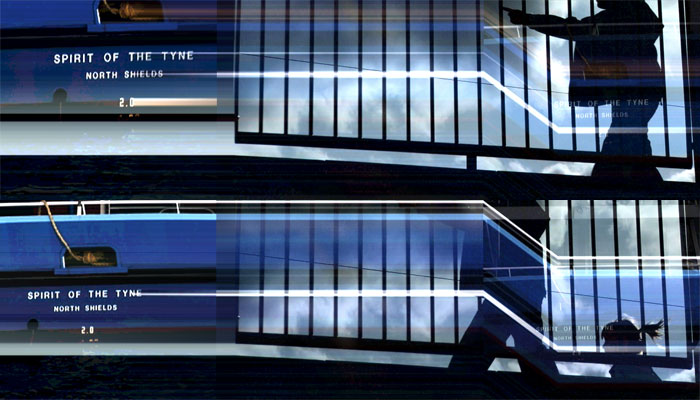

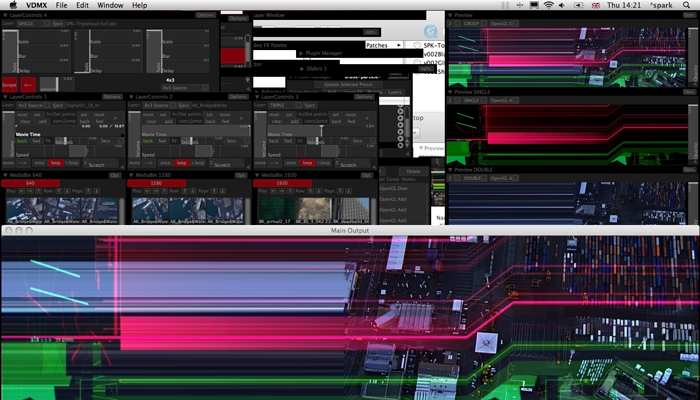

and what next for nine earths? to reach more people, it should spread beyond gallery installation; too few people can attend, from too little of society. to have more impact, it should engage people wherever they are, and those people should engage others where they find them. could it be a streaming tv channel? could it live in a browser? could it be… in their pocket? the same phone app that engages peoples to contribute hints and glimpses of their lives, could be the artwork itself? An integrated digital platform…

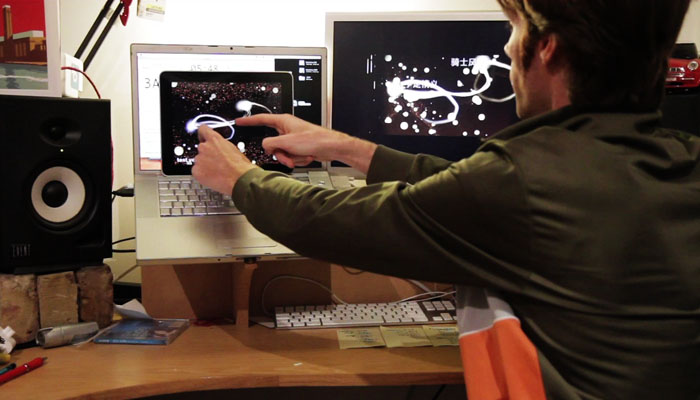

it’s clear to me the phone app needs to gathers video data, yes, but it should also engage people with their contributions. to be able to see their contributions in context, thematised with others. if there is value in commissioning the ethnography, in seeing patterns and drawing conclusions, the participants as well as the clients should be able to experience that too.

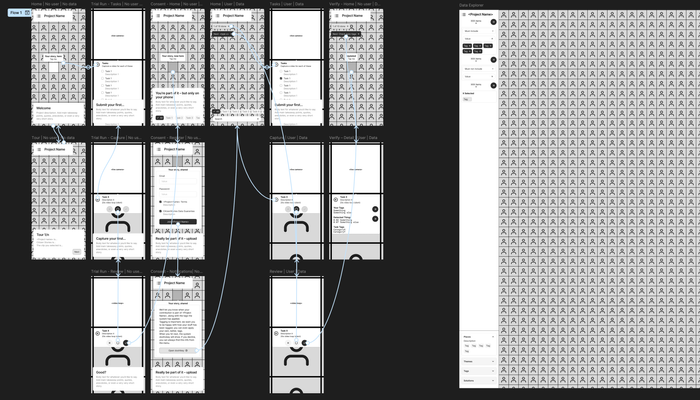

the missing recruitment and participation piece starts, then, with bringing the data explorer app for analysis into the crowd-sourcing app to gather video data. doing that right will enmesh value, ethics and a social virality. it’s what can live up to the name citizen stories. the wireframe pictured is my first pass at that, and i think it’s good.