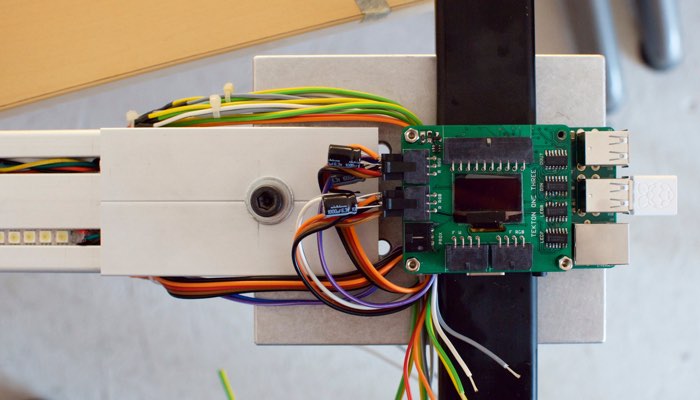

carriage blocks machined, pcb assembled, parts mounted and LED bars have LED strips fitted and on their way to being wired. damn fiddly, not without it’s trials and certainly time consuming, but looking damn sharp.

fitting the ‘dotstar’ LED strips in particular is both wonderful and frustrating. such a nice fit when fitted, but all sorts of trouble getting in and out, an action liberally aided by silicone lubricant. lots of silicone lubricant. but many gotchas: the rubber sheath stretches as you pull the assembly through, so woe betide you if you need to adjust afterwards or pull out again (which, this being both prototype and first assembly, you’ll end up doing a few times); the dotstars are not continuous strips and you either need to de-solder the appropriate joint of the 60/m low-density strips which sold as 5m rolls but are actually factory soldered 0.5m sections, or completely remove the copious silicone and whatnot of the 1m sections of 144/m high-density strips and solder together. just doing that on the bench could be unreliable, and when sheathed and pulled into the groove… yeah.