I built a thing, as part of D-Fuse for our gallery show Pattern & Noise. The following is a long exposition of the build, which – along with this text, apologies – got quite tortured. It’s lifted from the project post at South London Makerspace, where I’m a member and did the initial build.

Concept

TEKTŌN is an on-going collaboration between Mike Faulkner and Paul Mumford. A series of virtual machines are driven parametrically to make light patterns in space.

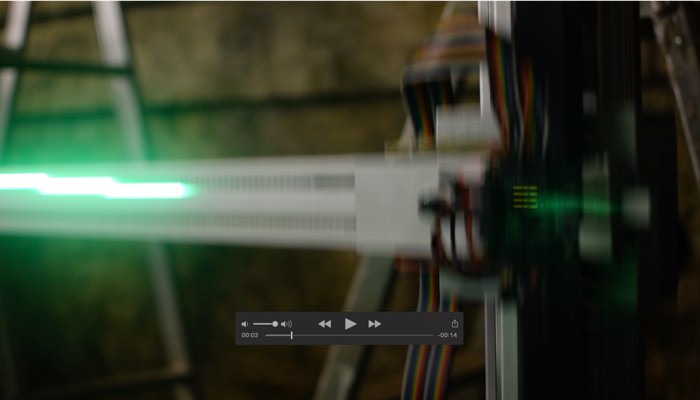

TEKTŌN ONE THREE’s mechanism is two horizontal bars of light points that animate up and down. At time of writing, this mechanism is modelled and animated in Touch Designer by Paul, realised on-screen in an audio-visual recording Paul made, and realised in physical space… with what you see here, by me, Toby Harris.

This physical machine was developed to be a centrepiece of the D-Fuse gallery show “Pattern & Noise” at Wood St. Galleries, Pittsburgh, USA. This meant we – D-Fuse, our artist collective – had a budget to work from, but also a hard deadline to ship to.

Tekton One Three - Touch Designer Simulation from Labmeta on Vimeo.

Design

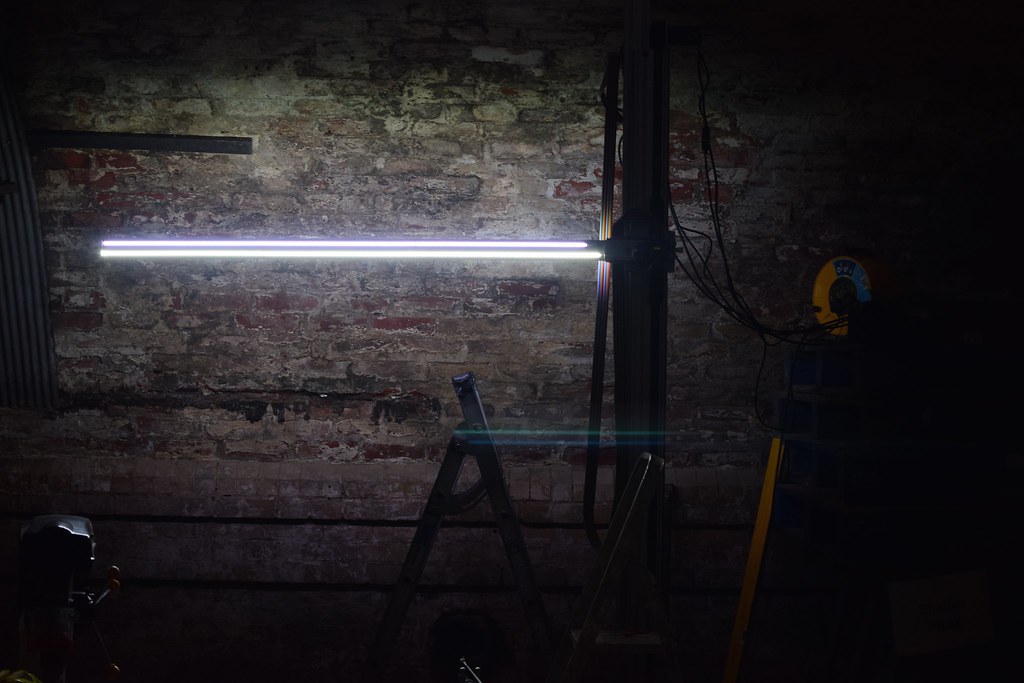

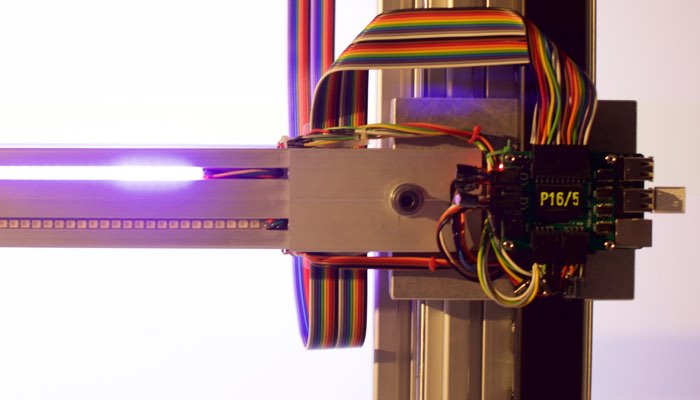

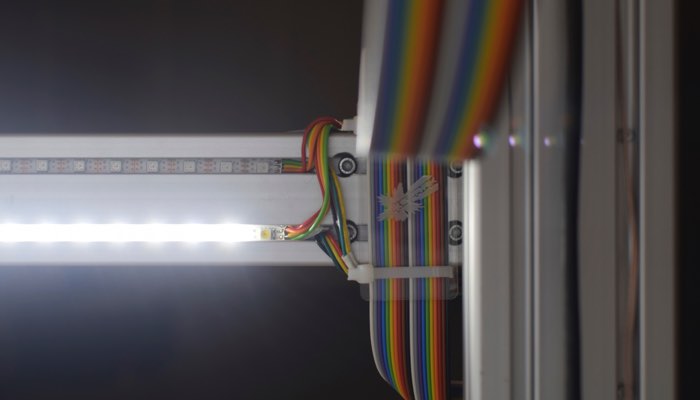

Initial discussions of models, lightweight structures and hacking filming equipment fell to the wayside as desire for the aesthetics of industrial machines aligned with the forces of filling the large gallery space and running reliably for three months. The brief that formed was for a machine that could move two LED filled bars ~1.5m long vertically for a 2m run, to paint light in space without any structure visually interfering with that image. We knew dynamic constraints of a physical machine couldn’t get us to where the screen based simulation was, but we wanted to get as close as we sanely could.

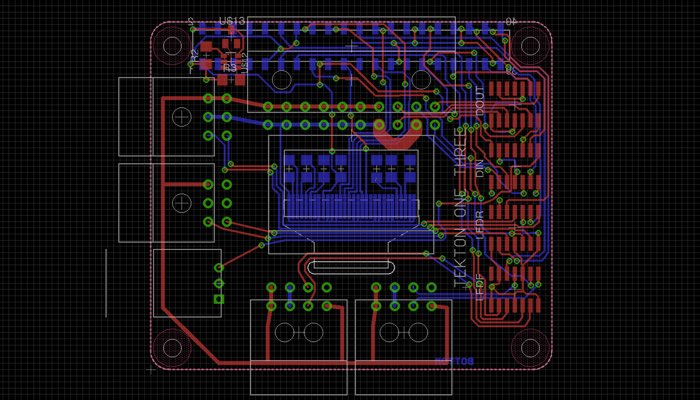

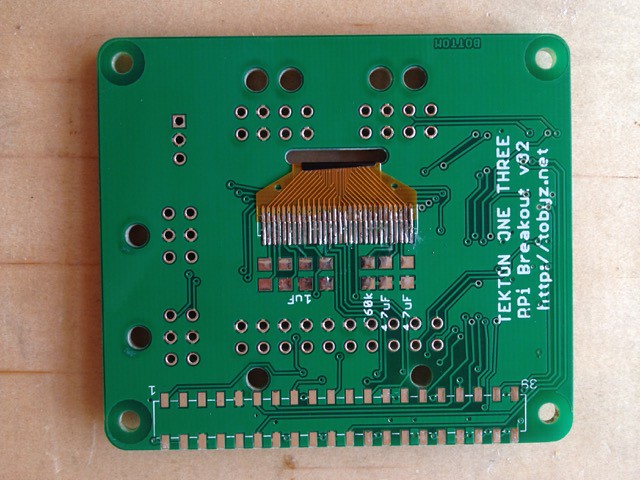

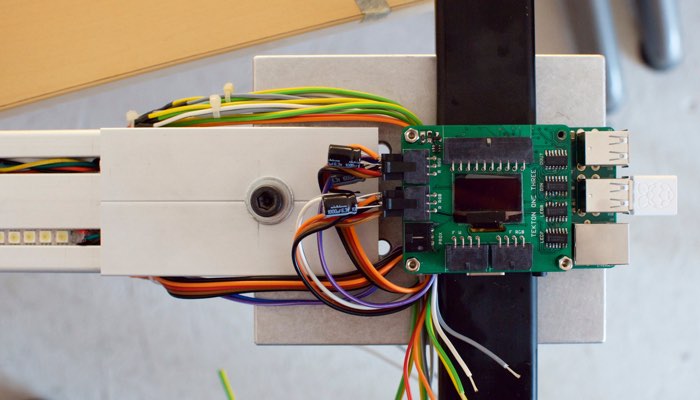

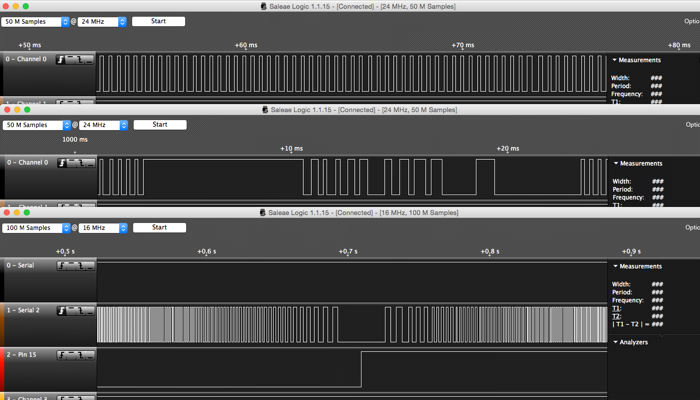

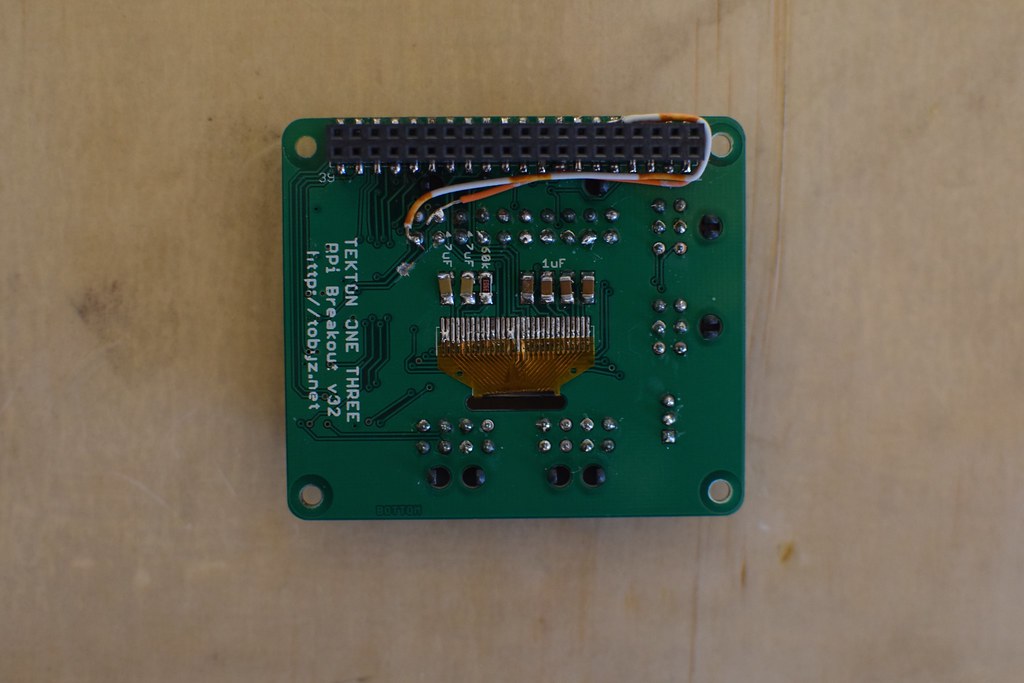

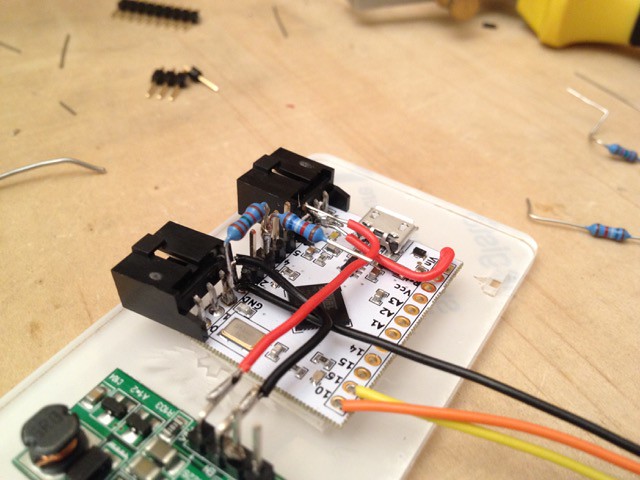

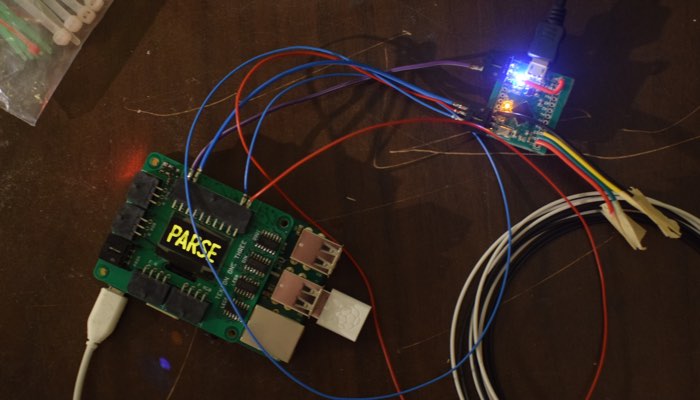

The project was well-timed to take advantage of the new APA102 individually addressable LEDs, ‘dotstar’ as sold by Adafruit. Unlike previous WS2812 ‘neopixels’, they can be driven by a Raspberry Pi, and driven fast. Using a Raspberry Pi was interesting as amongst other things having a full wifi stack and linux software for, say OSC could mean easy sync between multiple controllers and realtime control from Touch Designer.

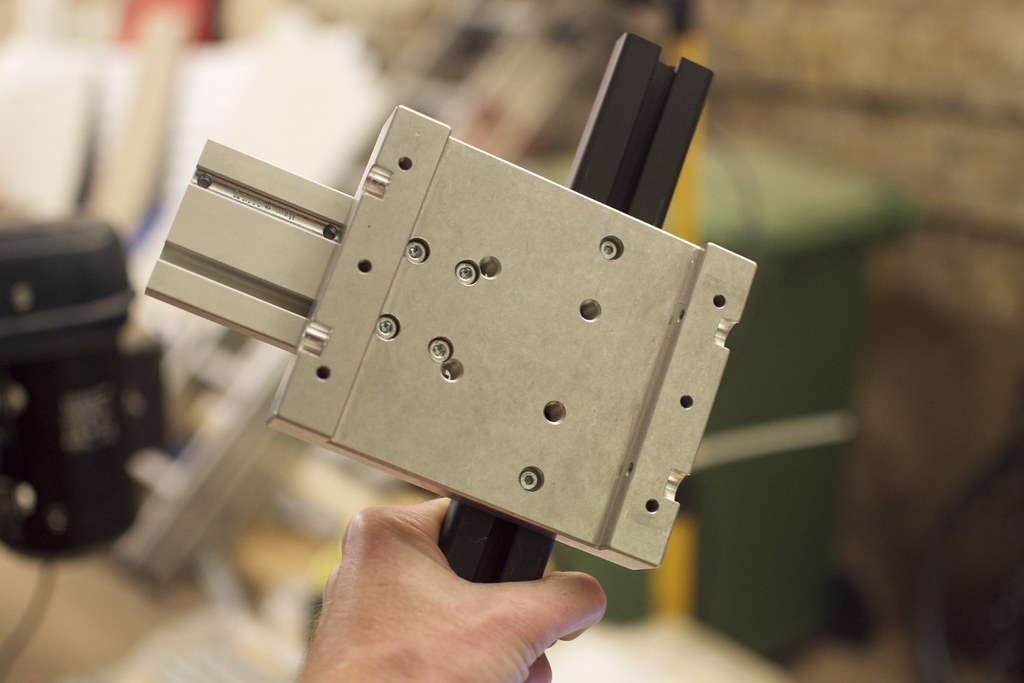

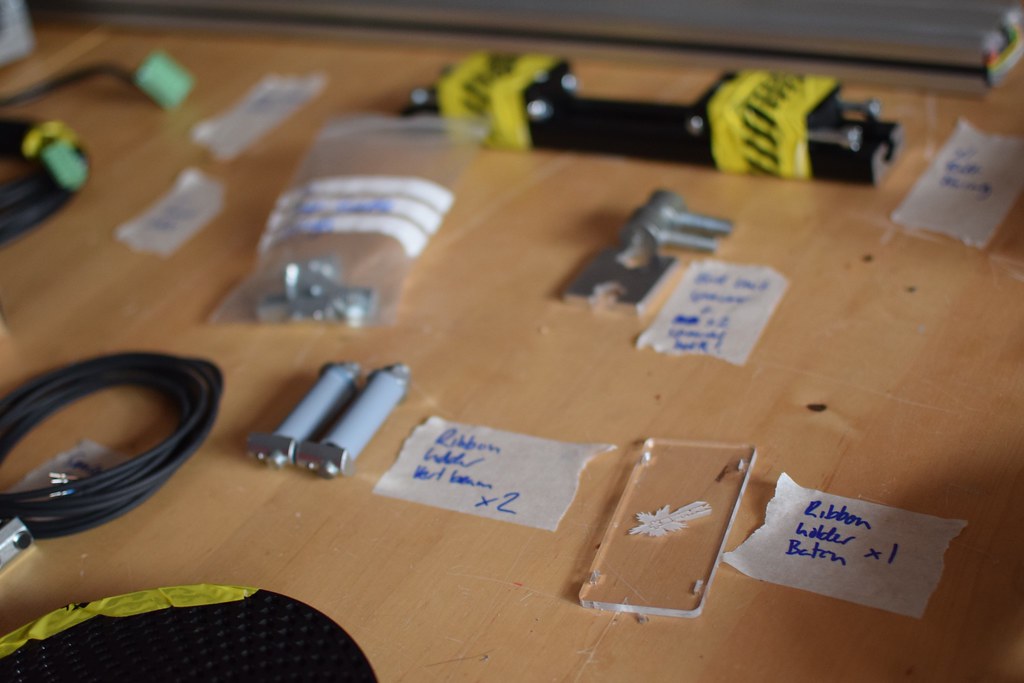

Mechanically, research led to either buying a pre-made linear slide or assembling one ourselves from a system of parts. Assembly ourselves also implying disassembly for transport, we opted for the latter knowing that shipping was going to be a much easier problem if we could break down the machine into standard, smaller packages. There was also the benefit of no lead time, as they’re parts taken from stock rather than requiring a factory to make the slide to length.

There are countless Aluminium profile systems but only the MB Building Kit for Mechanical Engineering from Item had the range of niche accessory parts to solve whatever need I had while spec’ing up options for the machine. And they had a US operation, too. The option that won had 3-4m long floor-ceiling bars that we would buy locally rather than ship, with a 2.3m bar we would mount slide rails on, and a 1.6m bar to cantilever out with LEDs. The mechanical fittings for the belt drive we could remove for transport, giving quite an efficient pack: two tubes and a flight case or two.

Item don’t supply motors but Zapp Automation – who we almost bought LEZ slides from – had the full range of keenly priced Leadshine Easy-Servo motors in-stock which seemed a good bet, particularly in having a driver unit qualified for the motors that would isolate any controller I made from the realities of motors, mechanics, and what would happen if something went wrong there.

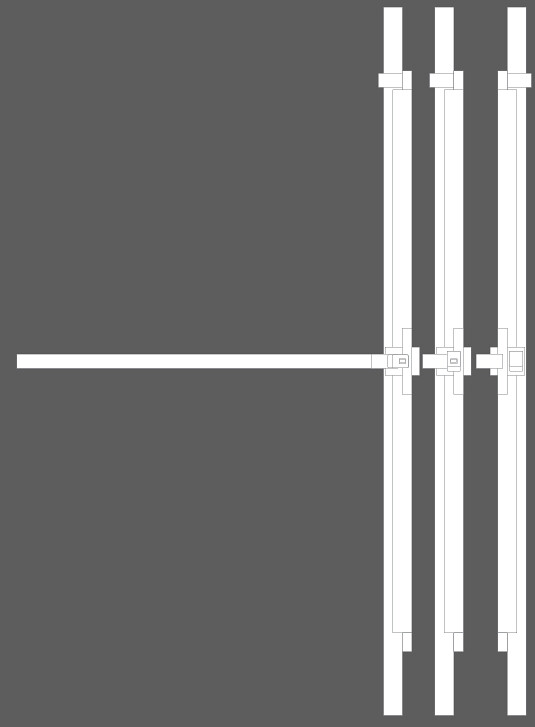

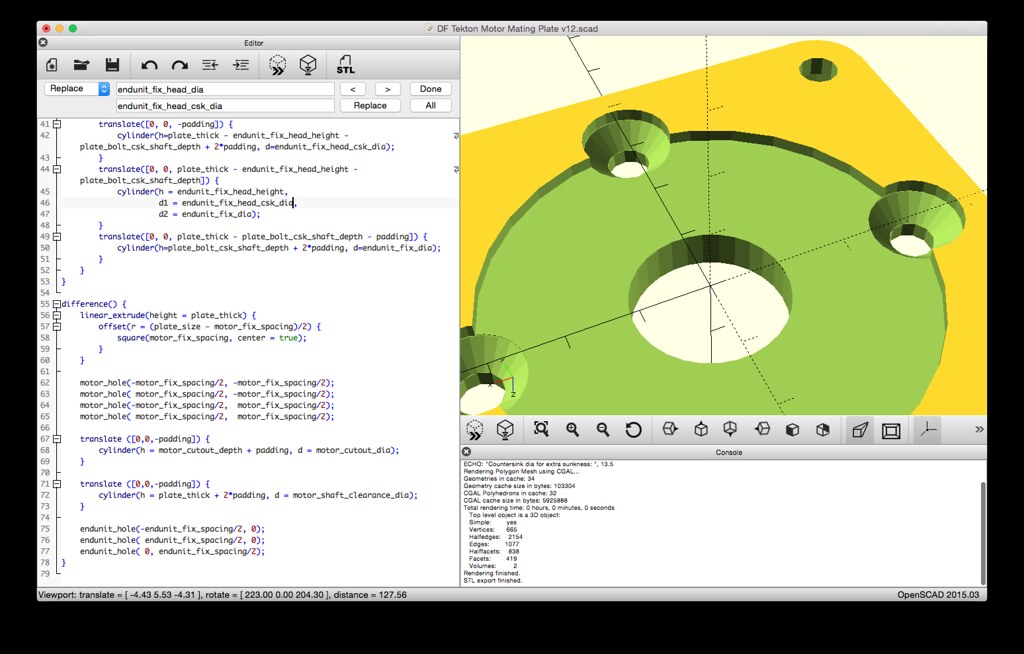

The design process was mostly scribbles and an ever-growing spreadsheet, but it did at some point need an accurate drawing as sanity check for dimensions. And so, the above.

Build

Is in diary posts below.